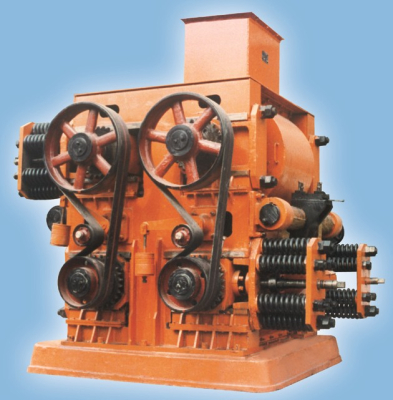

Roller crusher with two teeth 600×750 mm

The double tooth roller crusher is designed for crushing hard coal in a coal mine or beneficiation plant, and can also be used for crushing other medium and low hardness brittle materials. Hydraulic adjustment, central lubrication of toothed roller bearings. Tooth shape design optimization, tensile shear crushing selection, high efficiency and low consumption, uniform grain yield. The machine also has the advantages of small volume, low noise, simple structure and convenient maintenance.

The operating principle of the two-tooth roller crusher is based on the action of rolling force and crushing force. When the material enters the crushing cavity, it is forced between the two rollers by the rodent force of the rotating roller and the compression and grinding force of the roller, causing the material to break down. The broken small particles are thrown tangentially to the direction of rotation of the rolls and fall under the machine through the gap between the axes of the two rolls, forming the finished product. This type of crusher is simple in structure, easy to operate and maintain, has long teeth and small diameter rolls. It uses high-speed rotation to separate the material and instantly destroy it, forming a high-performance mechanism.

Name |

Parameter |

|

Rotor length X(mm) |

Φ600×750 |

|

Max. feed size(mm) |

≤600 |

|

Change the size of the unloading gate(mm) |

≤125 |

|

Capacity(m³/h) |

60-125 |

|

Engine |

Type |

Y200L/Y225M |

Power(KW) |

22 |

|

revolution(r/min) |

50 |

|

Size(L*W*H)(mm) |

3265×2780×1025 |

|

Equipment weight (without engine)(Kg) |

6950 |

|