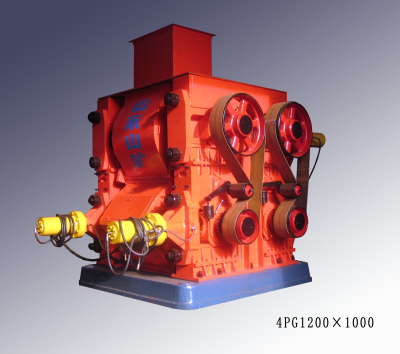

Roller crusher with two teeth 400×500 mm

The double tooth roller crusher is designed for crushing hard coal in a coal mine or beneficiation plant, and can also be used for crushing other medium and low hardness brittle materials. Hydraulic adjustment, central lubrication of toothed roller bearings. Tooth shape design optimization, tensile shear crushing selection, high efficiency and low consumption, uniform grain yield. The machine also has the advantages of small volume, low noise, simple structure and convenient maintenance.

Double teeth roller crusher has the advantages of small size, large crushing ratio, low noise, simple structure, convenient maintenance, high productivity, uniform particle size of broken materials, low crushing ratio, convenient maintenance, sensitive overload protection, safe and reliable performance . This machine mainly uses a special abrasion-resistant roller to separate the material to form a high-performance mechanism. The two-tooth roller is driven by a universal clutch, and the gap between the rollers is adjusted using spacers. The machine is mainly composed of fixed roller, movable roller, reducer, universal coupling part, all using plain bearings, smooth transmission, use and maintenance are very convenient.

Name |

Parameter |

|

Rotor length X(mm) |

Φ450×500 |

|

Max. feed size(mm) |

≤200 |

|

Change the size of the unloading gate(mm) |

≤100 |

|

Capacity(m³/h) |

20-55 |

|

Engine |

Type |

Y180L |

Power(KW) |

15 |

|

revolution(r/min) |

64 |

|

Size(L*W*H)(mm) |

2208×2048×912 |

|

Equipment weight (without engine)(Kg) |

3645 |

|