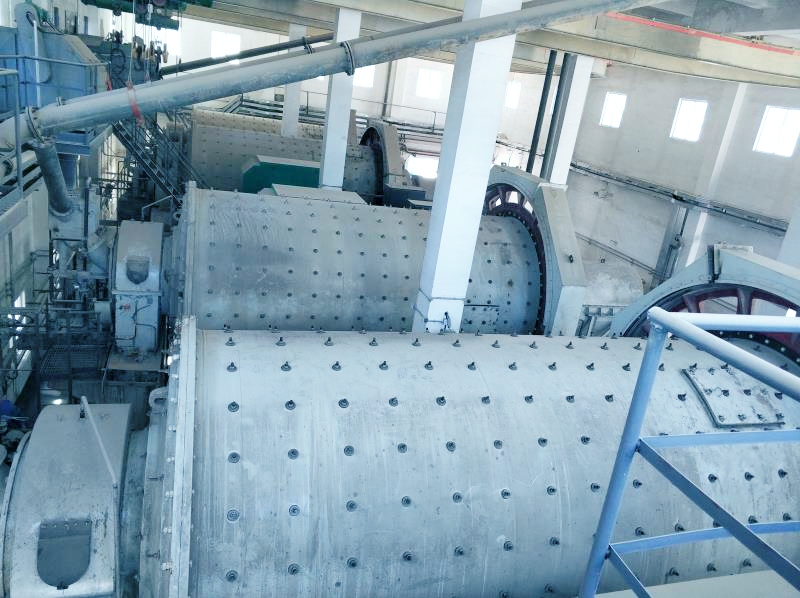

Rod mill

During the ore grinding process, the grinding media contact the ore in a linear state, so they perform the function of selective grinding. The grain size of the product is uniform, the content of overgrinding particles is low. When used for coarse grinding, the productivity of a rod mill is much higher than that of a ball mill with the same specification.

MB series rod mills are widely used in primary grinding of artificial rock sand, metallurgical steel slag processing, mineral processing plants, power generation and chemical plants. The grinding medium located in the rod mill drum is a steel rod, usually the wet overflow type is used. The mill has the characteristics of uniform product size, less over-grinding phenomenon, higher grinding efficiency and easy replacement of worn parts. It is composed of transmission part, rotating part, main bearing, feeding and unloading device, auxiliary transmission device, lubrication device, electric control, etc.

Application of Rod Mill

The rod mill is used in metallurgical and non-metallurgical industries, reservoirs and glass building materials to grind various ores, rocks and artificial sand, which require a uniform product grain size. The energy efficient rod mill produced by our company adopts rolling bearings instead of sliding bearing bushing. This will save 10-20% energy compared to plain bearing support and increase production capacity by 10-20%.