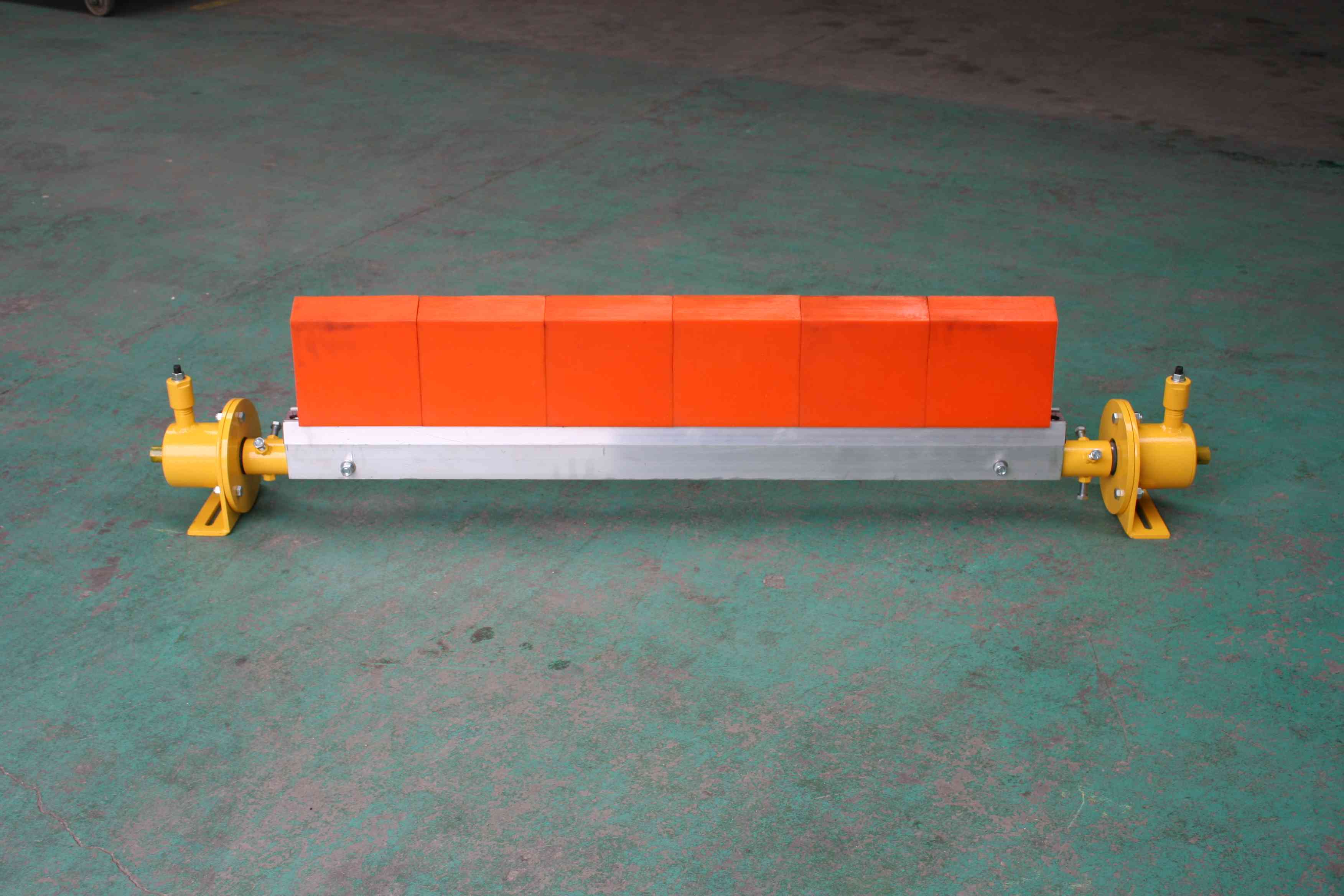

Scrapers for conveyor belts

Polyurethane cleaner is a new generation of cleaners developed and produced by the company. For its manufacture, high-quality polyurethane materials are used, which have such properties as high static, non-stick material, wear resistance, corrosion resistance, no damage to the belt, long service life, and the possibility of automatic wear compensation.

Characteristics of polyurethane scraper:

1. The polyurethane scraper is made of polyurethane material, which has both high plastic strength and high

elasticity of rubber.

2. Polyurethane scraper has ultra-high wear resistance, which is more than 5 times higher than ordinary rubber and plastic products.

3. The hardness range of polyurethane scrapers is wide, 60A-95A hardness range.

4. Polyurethane scraper is oil and solvent resistant, suitable for cleaning all kinds of materials.

5. Polyurethane scraper has high strength, clean scraper and does not damage the belt.

6. The polyurethane scraper has the property of automatically compensating for wear, and the blade head of the front part remains sharp at an angle after wear, so it can be used after adjusting the position of the fastening device.

7. The polyurethane scraper has good straightness, no material leakage, and the unique curved surface design can make the logistics slide smoothly, and it is not sticky.

8. Tonda polyurethane scraper has special antistatic fire retardant properties, does not carry hidden dangers, and is safe to use.

9. The polyurethane scraper is easy to install and easy to replace.

Peculiarities:

1.Installation position: head pulley or unloading pulley

2.High wear-resistant polyurethane blade will not damage the conveyor belt.

3.Urethane blade is compatible with tape connection, even mechanical connection such as tape fastening.

4.Both single urethane blades and segmented urethane blades are available.