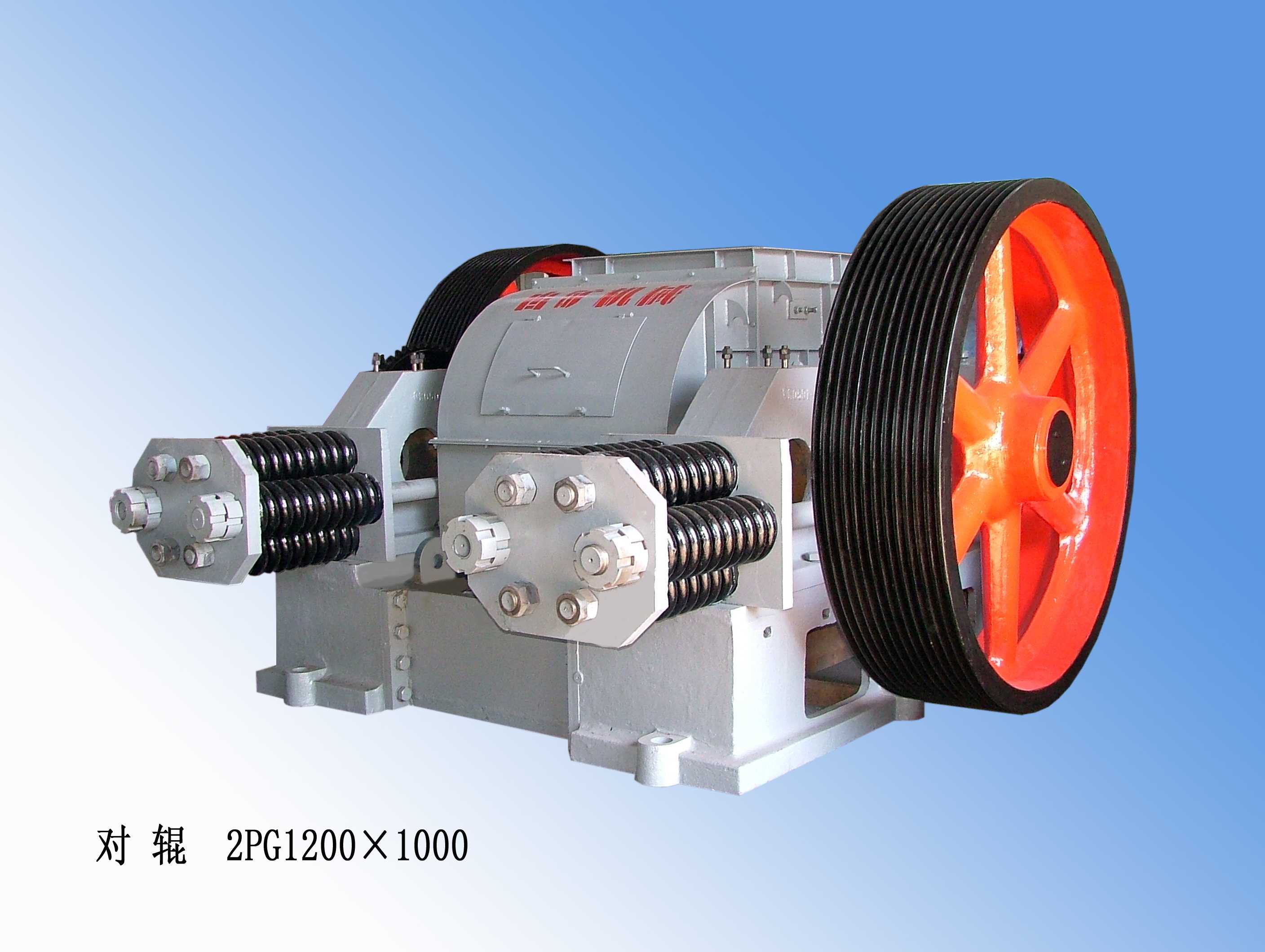

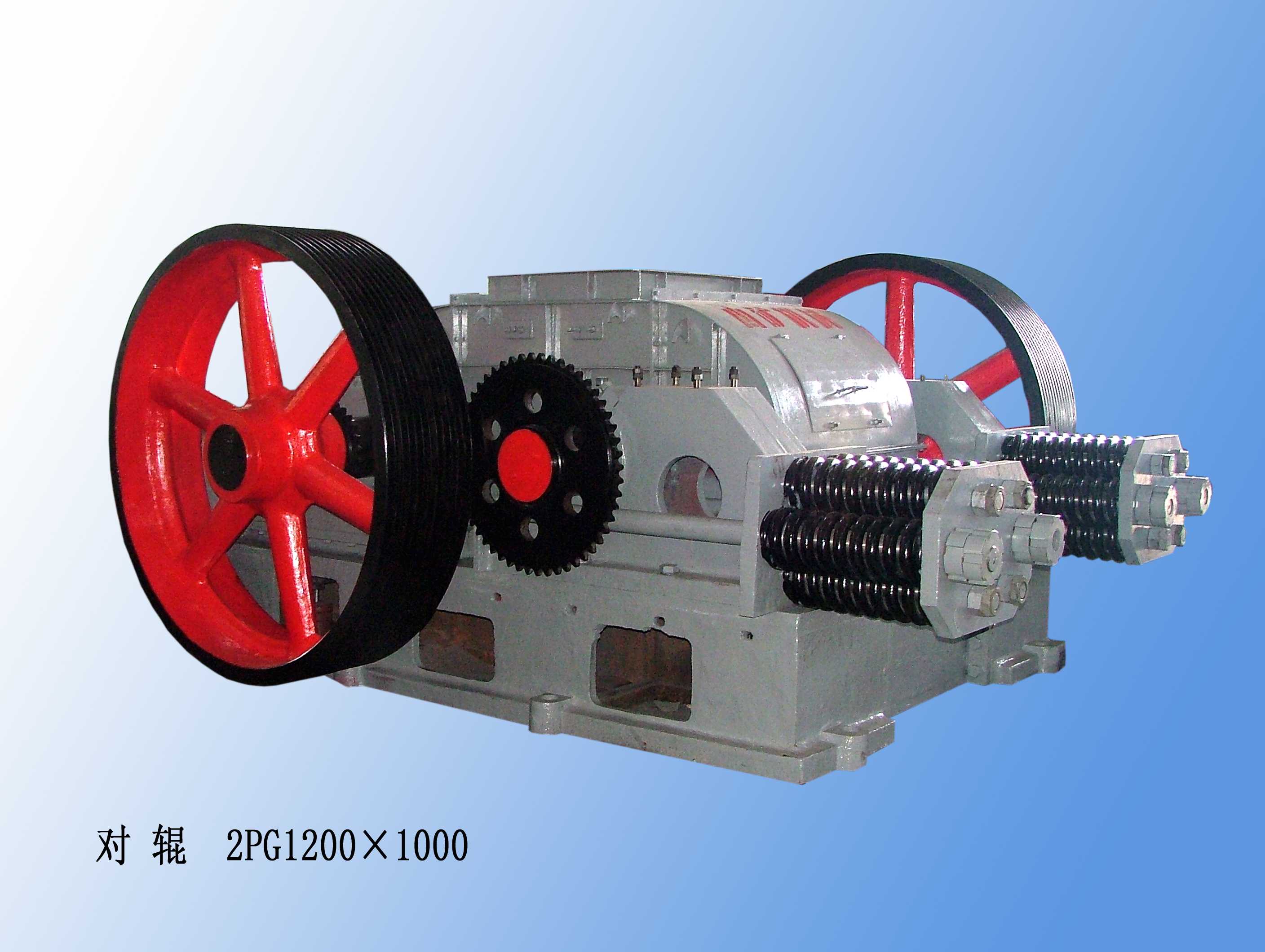

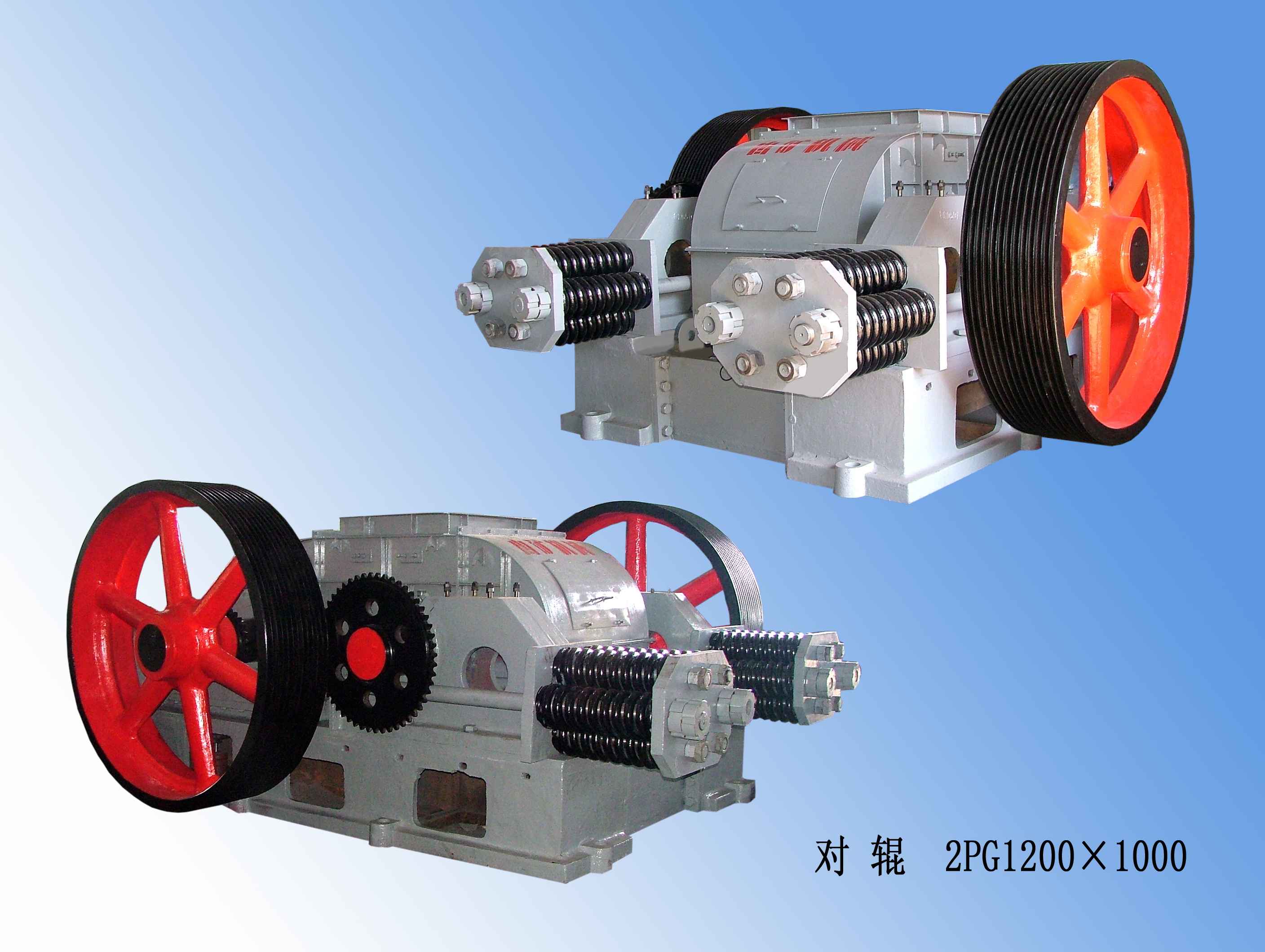

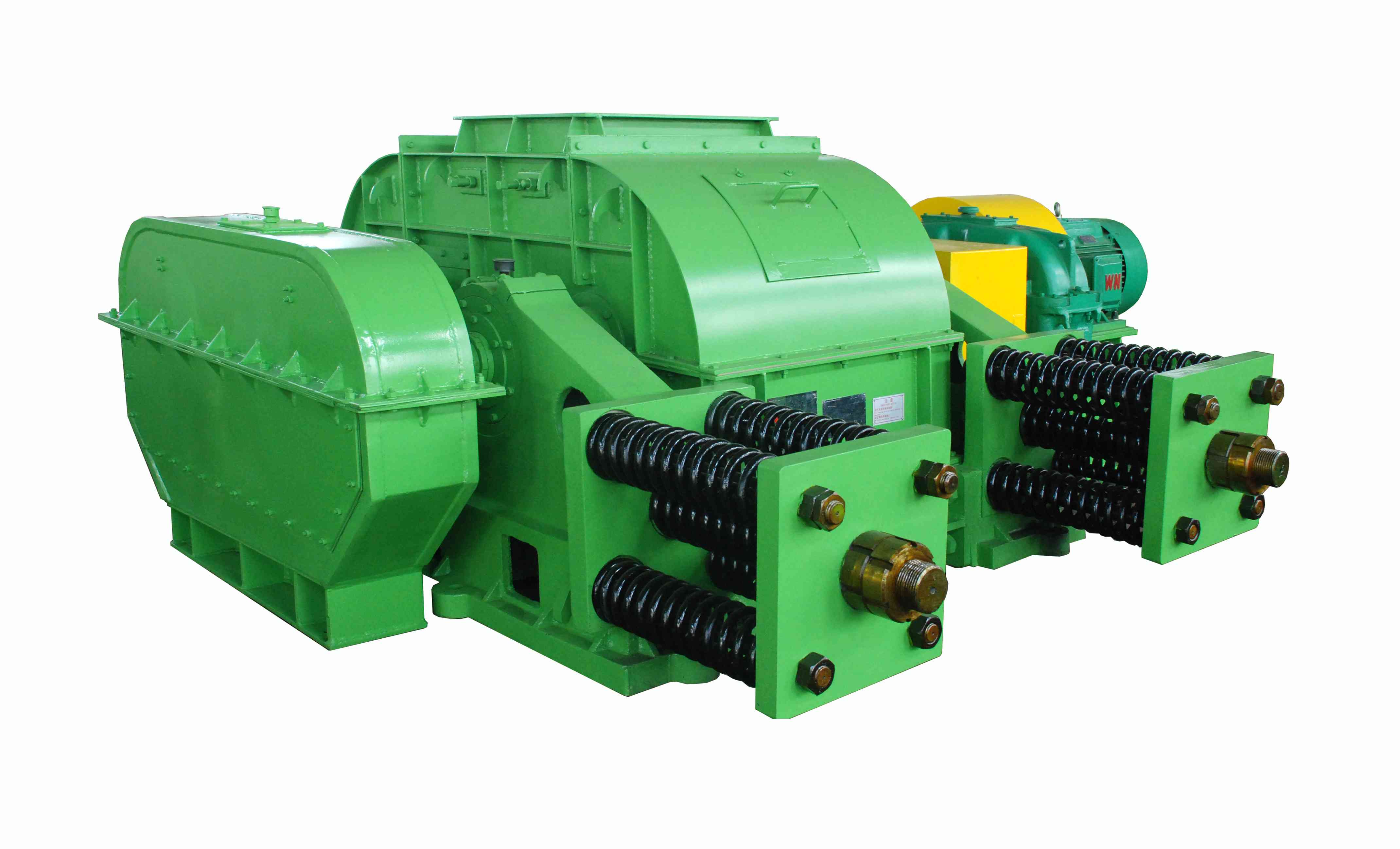

Double roll crusher

Roller crusher is widely used for crushing hard and medium hard materials in industrial sectors such as metallurgy, building materials and refractories. It is characterized by low noise level, small amount of powder dust, reliable operation and ease of maintenance.

It is a medium and fine crusher with a simple, compact and lightweight structure. This kind of crusher has a large grain size adjustment range and a wear roller repair cutting device, which can easily adapt to wet material and discharge the material smoothly well. Since the discharge size of such a crusher is very uniform, almost without over-excess or under-excess, it can be used for crushing limestone, marl shale, brick, slag, clinker feldspar, coke, etc., especially in the metallurgical industry for crushing raw coal before stove or coal before classification.

The machine is composed of body, rollers, drive shaft and base frame, etc. During operation, two rollers rotate in different directions, driven by a V-belt combined with a motor, and the material must be broken into the required grain size by adjusting the gaps between the two rollers.

Model |

Feed size (mm) |

Outlet size(mm) |

Capacity(t/h) |

Engine power(kw) |

Weight(kg) |

2PG400X250 |

≤25 |

1-8 |

5-10 |

11 |

1500 |

2PG500X400 |

≤30 |

1-10 |

8-20 |

22 |

3200 |

2PG610X400 |

≤40 |

1-20 |

13-35 |

30 |

4500 |

2PG610X800 |

≤40 |

1-20 |

15-40 |

37 |

12250 |

2PG750X500 |

≤45 |

1-20 |

15-40 |

37 |

12250 |

2PG750X700 |

≤45 |

1-20 |

20-50 |

44 |

14000 |

2PG900X500 |

≤55 |

1-40 |

20-50 |

44 |

14000 |

2PG900X900 |

<65 |

1-50 |

20-70 |

37X2 |

16800 |

2PG900X1200 |

<65 |

1-50 |

25-90 |

55X2 |

20800 |

2PG1200X1000 |

<70 |

1-60 |

25-100 |

45X2 |

40200 |

2PG1200X1200 |

<70 |

1-60 |

30-120 |

75X2 |

41980 |