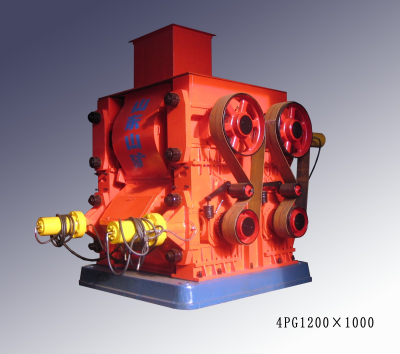

Impact crusher 1300*1500 mm

The 1300*1500mm impact crusher can be used not only as the first primary crusher, but also as the second and third crusher. It can process materials with a side length of 100-500mm and crush stones below medium hardness, such as granite, pebbles, limestone, quartz, coal mines and other materials.

Features: Crushing and forming functions, high productivity, cube-shaped final products, adjustable discharge opening, low abrasion, convenient operation and maintenance.

1.Model:PF-1315

2.Rotor length X length:f1300×1500(mm)

3.Max. feed size:150~350(mm)

4.Capacity:100~250(t/h)

5.Power:180~315KW

6.Overall size(LXWXH): 2230×3515×1515mm

7.equipment weight: excluding engine: 23000 kg

Notes: The power shown in the table is obtained under the following conditions:

1. The material to be crushed is ore.

2.The strength of the ore material against pressure is within 200MPa.

3.Surface water content within 2%.

4.bulk density is 1.6 t/m3.

5.Material supply along the entire length of the rotor is uniform and continuous.

An impact crusher is a crushing machine that uses impact energy to crush materials. During operation, the rotor rotates at high speed, driven by the motor. When material hits the impact bar, it collides with the impact bar and breaks, then is thrown toward the impact bar to be re-crushed before bouncing off the impact bar. Returns to the impact beam area for repeated crushing. The material enters the first, second and third impact chambers from large to small for repeated crushing until the material is crushed to the required particle size and discharged from the discharge opening.

Common wearing parts of impact crushers mainly include impact bars, side liners, impact plates, breaker plates, rotor, bearing, flat head bolt, spring, etc.