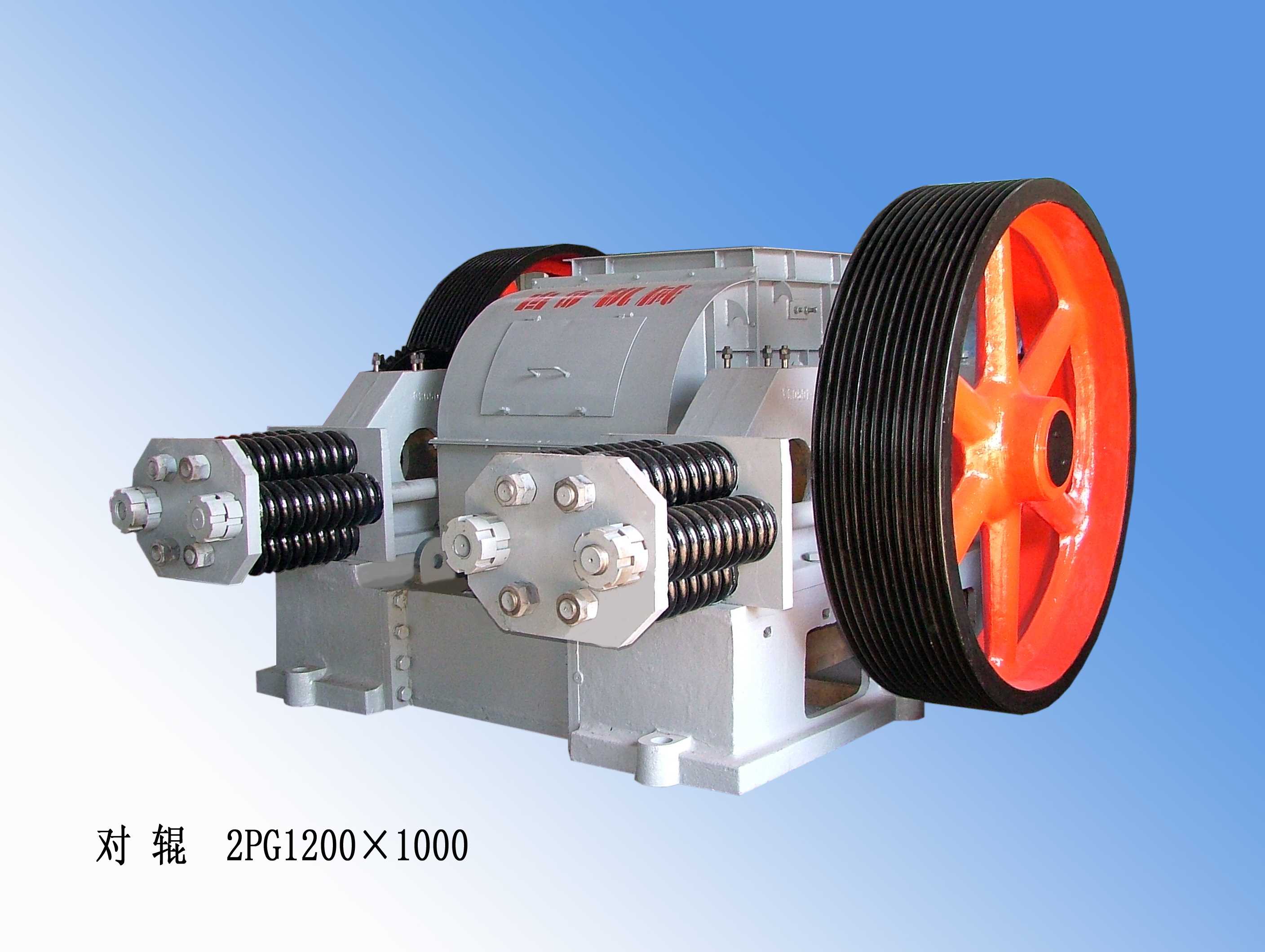

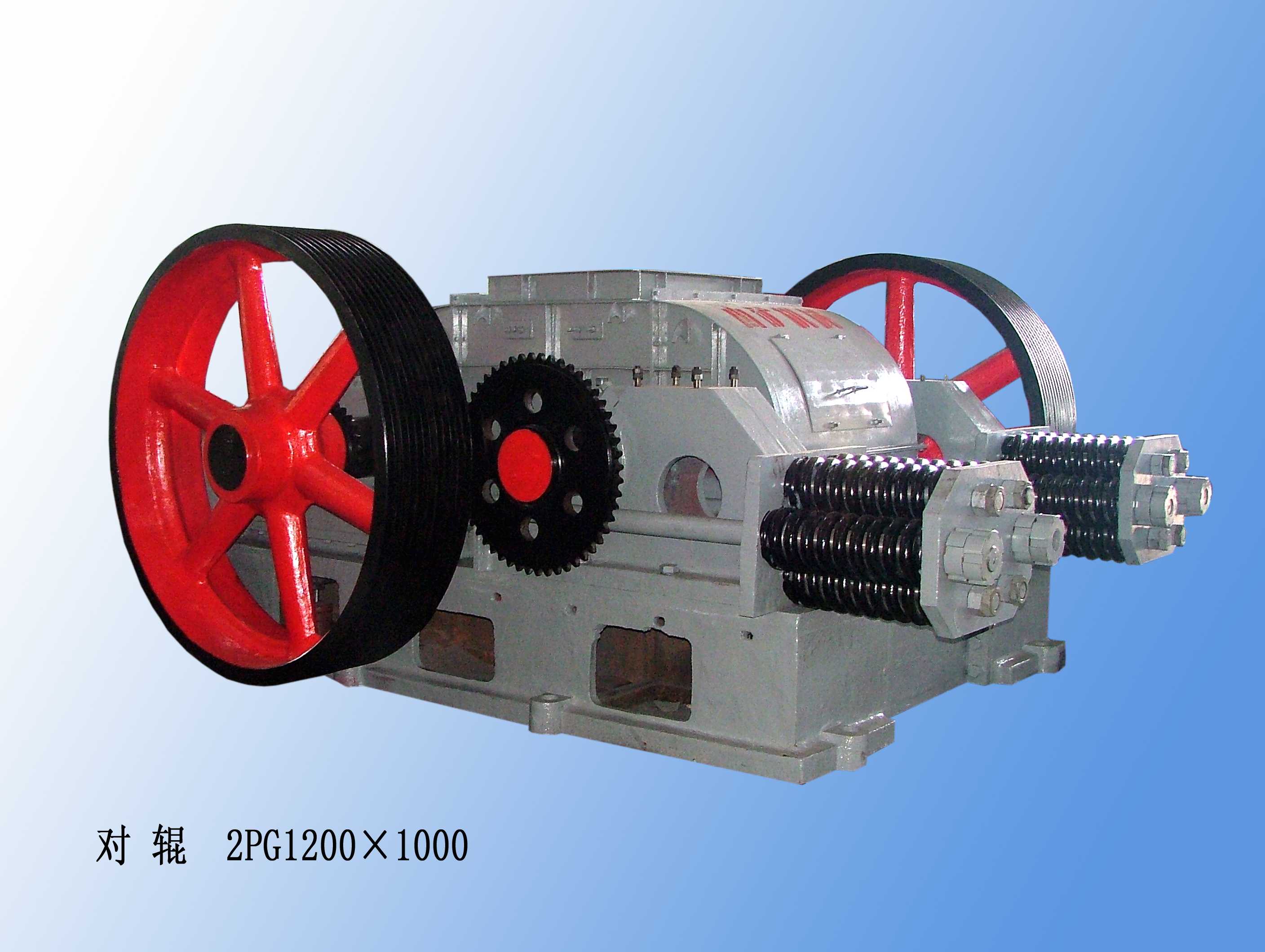

Twin roll crusher 1200×1000 mm

Double roll crusher is a kind of simple structure, compact, lightweight medium crusher, fine crusher, coal crushing particle size control range is large, with roller wear repair device and function, strong adaptation to material moisture, smooth discharge. Used for crushing limestone, marl shale, brick, slag, clinker, feldspar, coke, etc.

Twin roll crusher is a common crushing equipment used to crush raw materials to the desired particle size. It usually consists of two or more parallel rotating rollers, and the gap between the rollers can be adjusted to control the size of the crushed particles. The working principle of roller crusher is to crush raw materials into smaller particles through extrusion and shearing force between rollers, which is suitable for crushing various types of raw materials such as ore, coal, construction waste, etc.

MAIN TECHNICAL PARAMETER

Goods |

Parameter |

|

Roller diameter(mm) |

Φ1200 |

|

Effective roller length(mm) |

1000 |

|

Max. feed size(mm) |

40 |

|

Final grain size range adjustment(mm) |

0-8 |

|

Roller revolution(r/min) |

185 (during operation) 74 when cutting) |

|

Capacity(T/h) |

90 |

|

Engine |

Type |

1LG0280-4AA |

Power(KW) |

75X2 |

|

Revolution(r/min) |

1480 |

|

Voltage (V) |

415 |

|

Overall size(L×W×H)(mm) |

5300×4945×1950Excluding system part) |

|

Weight(Kg) |

38742 |

|