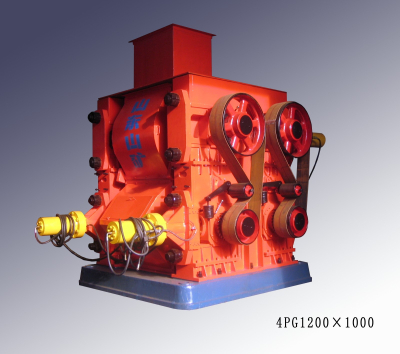

Reversible Impact Crusher 1413

1、No screen plate, overcoming the material temperature blocking problem.

2, the rotor can be positive and negative rotation, so that the hammer head and crushing plate wear evenly Jaw crusher is mainly used for all kinds of ores and large materials of medium size crushing, reducing the frequency of downtime to replace wearing parts.

3、 The discharge opening gap is adjustable, the granularity of the discharged material is uniform, with large output and low energy consumption.

4、The crushing chamber is easy to open, easy to replace wearing parts.

PCFK1413 reversible impact crusher is widely used in highways, coal mining, railways, airports and other areas where high shape stone materials are required. The equipment has the following features and characteristics:

1. Large crushing ratio and high crushing efficiency: With high-speed impact and repeated crushing, PCK1413 reversible impact crusher can quickly crush large materials to the required size, and is suitable for all kinds of materials with a compressive strength of no more than 360MPa.

2. Product cubic shape: The equipment, through the unique impact liner design, can produce good cubic stone shape to meet the high demand for the shape of stone materials.

3. No screen plate design: PCK1413 reversible impact crusher has no screen plate design, which avoids excessive crushing of materials in the crushing process and reduces the generation of coal dust.

4. Adjustable discharge size: The discharge size can be adjusted by adjusting the gap between the impact frame and the rotor frame.

5. High efficiency and energy saving: Using high manganese steel and double liquid alloy hammer head, which has high wear resistance and service life, and at the same time reduces energy consumption and improves overall efficiency.

1.Rotor diameter:1400(mm)

2.rotor length:1300(mm)

3.Feed particle size:≤90(mm)

4.Finishing particle size:≤3(mm)

5.Capacity:150~200(t/h)

6.Power:560KW